Keeping Wheels Rolling – Fleet Maintenance

PUD fleet and facility manager, Kenny Yingling, latches the heated storage compartment on the side of the line truck. Inside, climbing harnesses rattle on hooks.

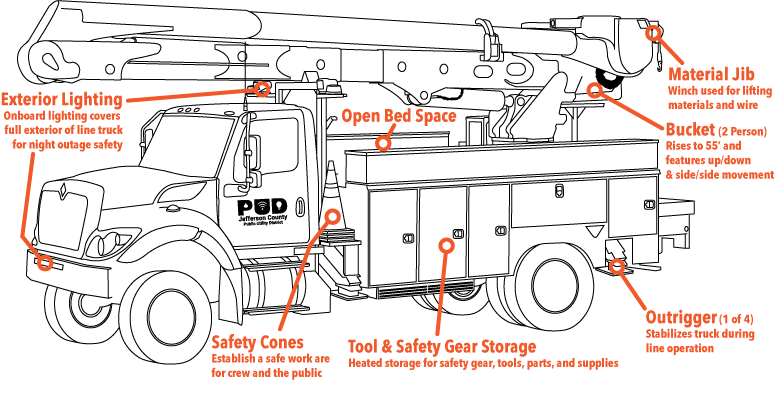

“Line trucks are basically a mobile office–our line crew has to have everything needed to fix an outage,” Yingling said, noting the weight does wear on vehicles and parts, but it’s essential for fast service.

“These are a different kind of dinosaur altogether,” Yingling said, while continuing inspection of the full-size, 8-ton vehicle. The term “dinosaur” is apt considering the sheer size of the vehicle and its extendable 55′ hydraulic arm with line crew bucket at the end.

“There is really nothing ‘routine’ about maintaining our fleet,” Yingling said, adding that he enjoys the variety his job offers. Yingling, who was born and raised in Port Townsend, is a veteran of fleet maintenance, joining the PUD in 2019 after 10 years with Jefferson Transit.

The PUD has 11 line vehicles: 4 full-size bucket trucks, 3 digger derricks (designed with a boring attachment for pole placement), and 4 smaller single-person truck-mounted buckets. Yingling handles maintenance for the entire line fleet.

Line vehicles, complete with powerful diesel motor and rugged build, allow line crews to access challenging outage areas. They also offer a unique challenge due to their almost continuous run time in the field. There’s little downtime for a line truck, as the motor also powers the hydraulic system essential for boom operations. Heavy run time means constant maintenance from filter replacements, oil changes, and general wear items like exterior safety lighting. Even a simple tire change requires use of a forklift due to size.

Yingling’s world extends beyond just the parts of a line truck contacting the ground.

Single and two-person buckets extend several stories in the air and can lift large loads like pole-mounted transformers with the material jib. Components must be in top working shape to operate in harsh conditions and for longevity of the vehicle.

Single and two-person buckets extend several stories in the air and can lift large loads like pole-mounted transformers with the material jib. Components must be in top working shape to operate in harsh conditions and for longevity of the vehicle.

“Many line truck manufacturers won’t even take orders for new vehicles until 2026–and those have a price tag of at least $500K,” he said. Several line vehicles on the PUD fleet are long-term rentals. Yingling works to ensure all line trucks have annual inspections (to ensure line truck boom arms can handle contact from high voltage) for WSDOT certification and works with local service vendors for hydraulic operations and motor tune-ups. It’s all in a days work to keep the line fleet wheels rolling.